3 Reasons True Shot M Series is the Finest in the Market

The recently launched M1 Unmanned MWD (measurement while drilling) tool by True Shot is the first of its kind in the market. It uses state-of-the-art technologies to merge high-precision abilities with enhanced endurance and tolerance ideal for high-end drilling projects.

Here are three reasons why True Shot M Series is so popular right now.

High-Precision Sensors

The M1 Unmanned MWD measures the three-dimensional orientation of the drill, helping the operators maneuver the device during deviated well drilling. M1 has a sensory accuracy of +/-0.1° for inclination (vertical orientation) and +/- 0.25° for azimuth (horizontal orientation).

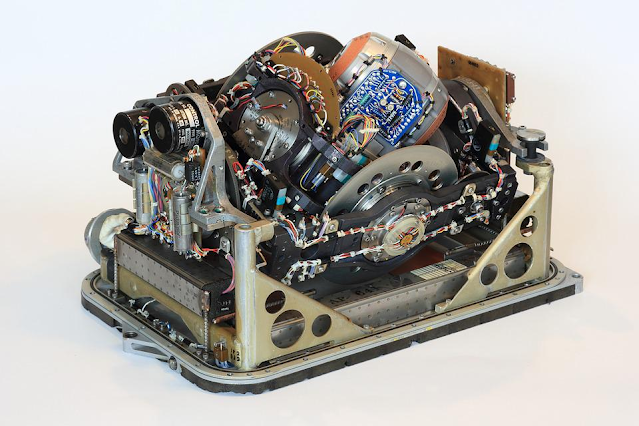

M1 uses three different types of sensors to measure orientation: magnetometers, accelerometers, and gyroscopes. Magnetometers work as a strong compass to measure the azimuth of the drill. Accelerometers measure the acceleration due to gravity which is known to always point downwards. They use the direction it reads to determine the inclination of the drill.

Gyroscopes work a little differently as they're not sensors per se. They are rotating flywheels with stored angular momentum. Since angular momentum is a conserved quantity, gyroscopes tend to resist any change in their orientation. They verify the measurements taken by other sensors, improving accuracy.

Powerful Mud Pulse

The information collected by sensors on the M1 Unmanned MWD can't be communicated to the operators using the traditional ways of communication. Data cables cannot survive the environment, and radio waves cannot get through the overburden.

M1 uses mud pulse telemetry technology. Unlike radio waves that travel through the electromagnetic field, mud pulse telemetry uses mud as a travel medium. Mid pulse transmits MWD data through pulses in the mud.

M1 is equipped with powerful motors capable of producing waves 50 times more powerful than gravitational acceleration. This is denoted on M1's specifications sheet as "50g."

Internal Logging

Mud pulse is highly effective at transmitting MWD data to operators on the ground. However, it consumes a lot of energy. Transmitting all the data collected by M1 is a time-consuming task, but the information needs to be logged somewhere.

M1 Unmanned MWD has internal data logging. It stores all the data from the sensors internally, which can be accessed by the operators. Engineers can also analyze this data later for troubleshooting. The M1 tool supports data logging for up to 1500 hours.

In addition to these features, the M1 Unmanned MWD from True Shot also has a high-pressure tolerance of 20,000psi and can operate in temperatures up to 135°C / 235°F. The complete specifications can be found on our M1 MWD System page. Check out the M Unmanned MWD system now!

Comments

Post a Comment